Search

Atlas

Real-Time Production Twin for Food Processing Plants

Manufacturer: Snellman Group (Food Processing)

Industry: Manufacturing

Type: System Twin

Integration: Digital Shadow

Sophistication: Informative Twin

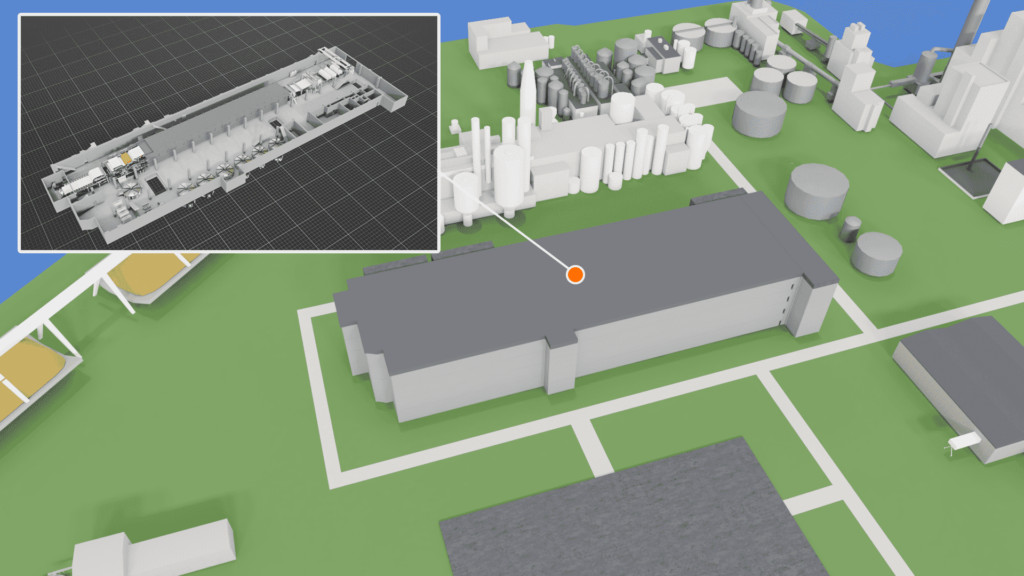

Snellman Group uses Process Genius’s 3D Digital Twin platform to visualise and monitor production across its meat-processing and ready-meal factories in real time. By connecting MES data, RFID tracking and facility layout into a virtual twin, Snellman gains immediate insight into line performance, cooking and cooling cycles, storage conditions, and hygiene zones — enabling better quality control, waste reduction, and swift reaction to deviations. The twin replaces static reporting with dynamic, visual factory oversight.

The Snellman Group — a Finnish, family-run food processing company headquartered in Pietarsaari — partnered with Process Genius to enhance production transparency. Transitioning from barcode-based to RFID-based tracking, Snellman deployed the Genius Core™ 3D Digital Twin across its plants (including Pietarsaari and Kerava). Process Genius+1

The digital twin renders a virtual replica of the physical plants and integrates data from existing systems (MES, RFID data, sensors). From day one, plant managers and staff gained real-time dashboards showing line-specific metrics, oven and cooling-tunnel occupancy, production throughput, storage status, and environmental conditions. This enables early detection of potential issues such as product waiting times, temperature deviations, hygiene-zone risks and storage mishandling. Process Genius+1

In the cooking department, for example, the twin logs when products enter ovens and when they exit for cooling — ensuring products do not overstay and spoil. Operators and quality-control staff receive immediate visibility if a batch exceeds the allowed cycle time, thereby preventing waste. Process Genius

Furthermore, the platform visualizes storage facilities and implements “traffic-light” views based on expiration dates, helping staff use raw materials and finished products before expiration — reducing spoilage. Process Genius

The accessible 3D-based twin replaces large spreadsheets and delayed reports with intuitive real-time visual information — reducing response times, enhancing quality control, and supporting compliance. According to Process Genius, the solution requires no change to existing monitoring systems or major IT investments. Process Genius+1

Thus, Snellman’s use of a production-level twin exemplifies how food-processing companies can apply digital-twin technology to improve operational visibility, quality assurance, and resource management without overhauling legacy systems.

<p>content and image: <a href="https://processgenius.eu/references-en/snellman/" target="_blank">https://processgenius.eu/references-en/snellman/</a></p><p>https://processgenius.eu/news/process-genius-genius-core-also-monitors-snellmans-latest-plant/</p>