Search

Atlas

Digital Twin for 3D-Printed Smart Pedestrian Bridge

Manufacturer: MX3D

Industry: Construction

Type: System Twin

Integration: Digital Twin

Sophistication: Predictive Twin

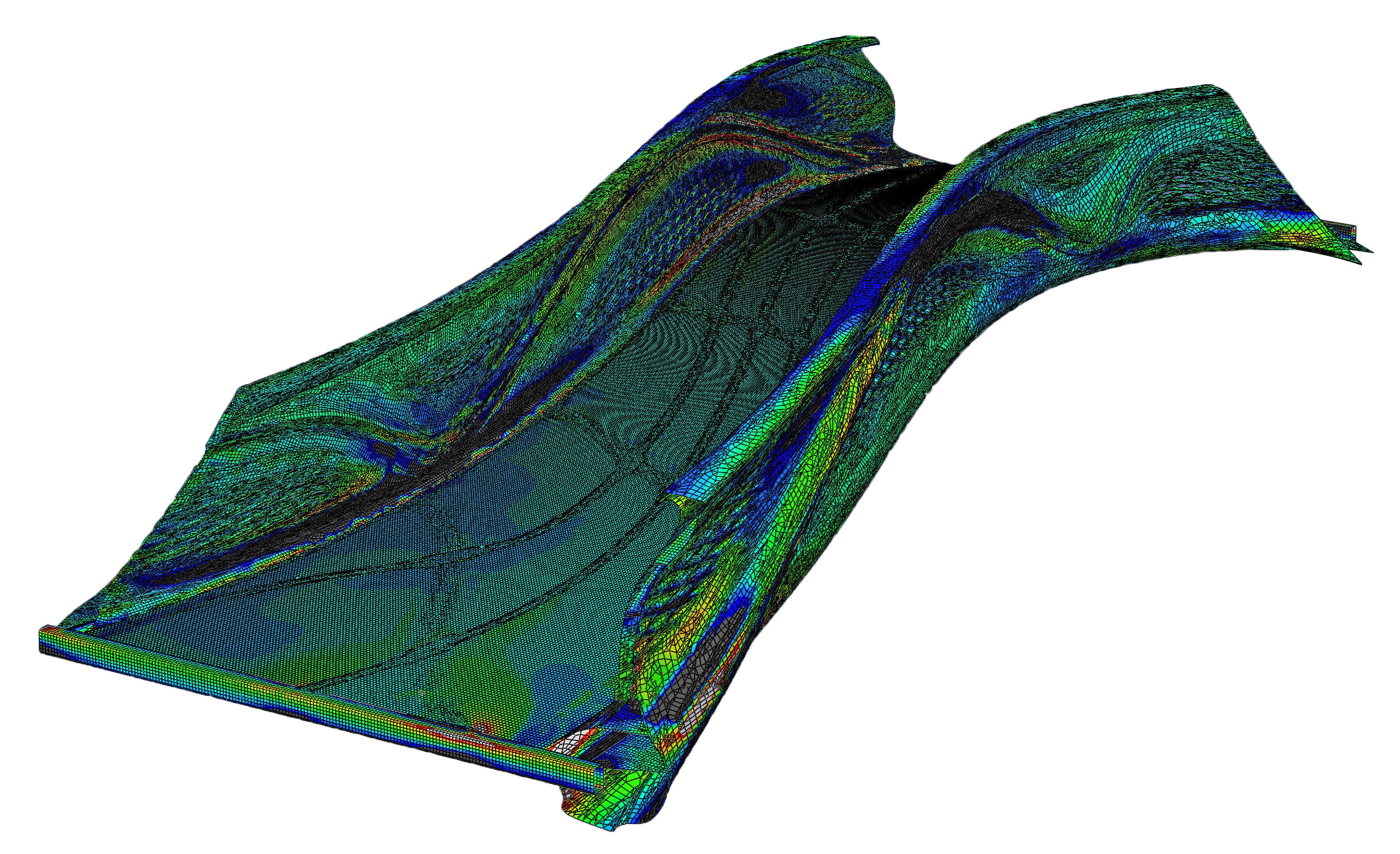

The pedestrian bridge delivered by MX3D represents a milestone in additive manufacturing combined with real-time monitoring and digital twin integration. Spanning a historic canal in Amsterdam, the stainless-steel structure is equipped with an advanced sensor network and paired with a Digital Twin that continuously mirrors its physical behaviour, enabling predictive maintenance and lifecycle optimisation.

Project Description

The MX3D Bridge is a 12-metre long, fully functional stainless-steel pedestrian bridge, created using robotic 3D printing technology. It was installed in Amsterdam’s historic city centre and serves as an exemplar of how advanced manufacturing, sensor systems and data analytics converge in infrastructure. The project involved a consortium including MX3D, engineering partner Arup, materials & fabrication partner ArcelorMittal, software & cloud partner Autodesk, as well as academic and research contributions from The Alan Turing Institute and AMS Institute. MX3D

Technology & Digital Twin Approach

A dense network of sensors was embedded in the bridge structure to capture structural responses (strain, displacement, vibration) as well as environmental parameters (air quality, temperature). MX3D These real-time data streams feed into the Digital Twin, which continuously updates the mathematical and computational model of the bridge. The twin allows engineers to compare actual performance with predictions, simulate what-if scenarios (for example increased pedestrian loads or extreme weather), and trigger maintenance or adaptation actions proactively. System behaviour, usage patterns, and environmental impact are all integrated into the model.

Operational Benefits & Outcomes

By leveraging the Digital Twin for monitoring and predictive analysis, the bridge project delivers several significant benefits:

- Enhanced safety through continuous health monitoring and early detection of anomalies.

- Extended service life due to condition-based maintenance rather than scheduled.

- Data-driven insights that inform future design of metallic 3D-printed structures.

- Real-time adjustment capabilities (for example adapting to changing load patterns).

Key Facts

- Location: Amsterdam, Netherlands

- Length: 12 m stainless-steel bridge launching in 2021. MX3D

- Printed using robotic 3-D print process; integrated sensor network; cloud analytics.

- Digital Twin enables real-time reflection of physical bridge, enabling predictive interventions.

Conclusion

This project demonstrates how infrastructure can be transformed into intelligent, data-driven assets using a comprehensive Digital Twin approach. The integration of additive manufacturing, sensor networks and analytics shows a pathway towards infrastructure that is not only built but continuously optimised, resilient and responsive to its environment.

<p><a href="https://www.turing.ac.uk/about-us/impact/bridging-gap-between-physical-and-digital" target="_blank">https://www.turing.ac.uk/about-us/impact/bridging-gap-between-physical-and-digital</a></p><p>https://mx3d.com/case/mx3d-bridge/</p>