In the ever-evolving landscape of technology, digital twins have emerged as game-changers across diverse industries, revolutionizing how we monitor, simulate, and optimize the performance of physical assets. Yet, the value of a digital twin lies not only in its existence but in the level of integration it achieves with its physical counterpart.

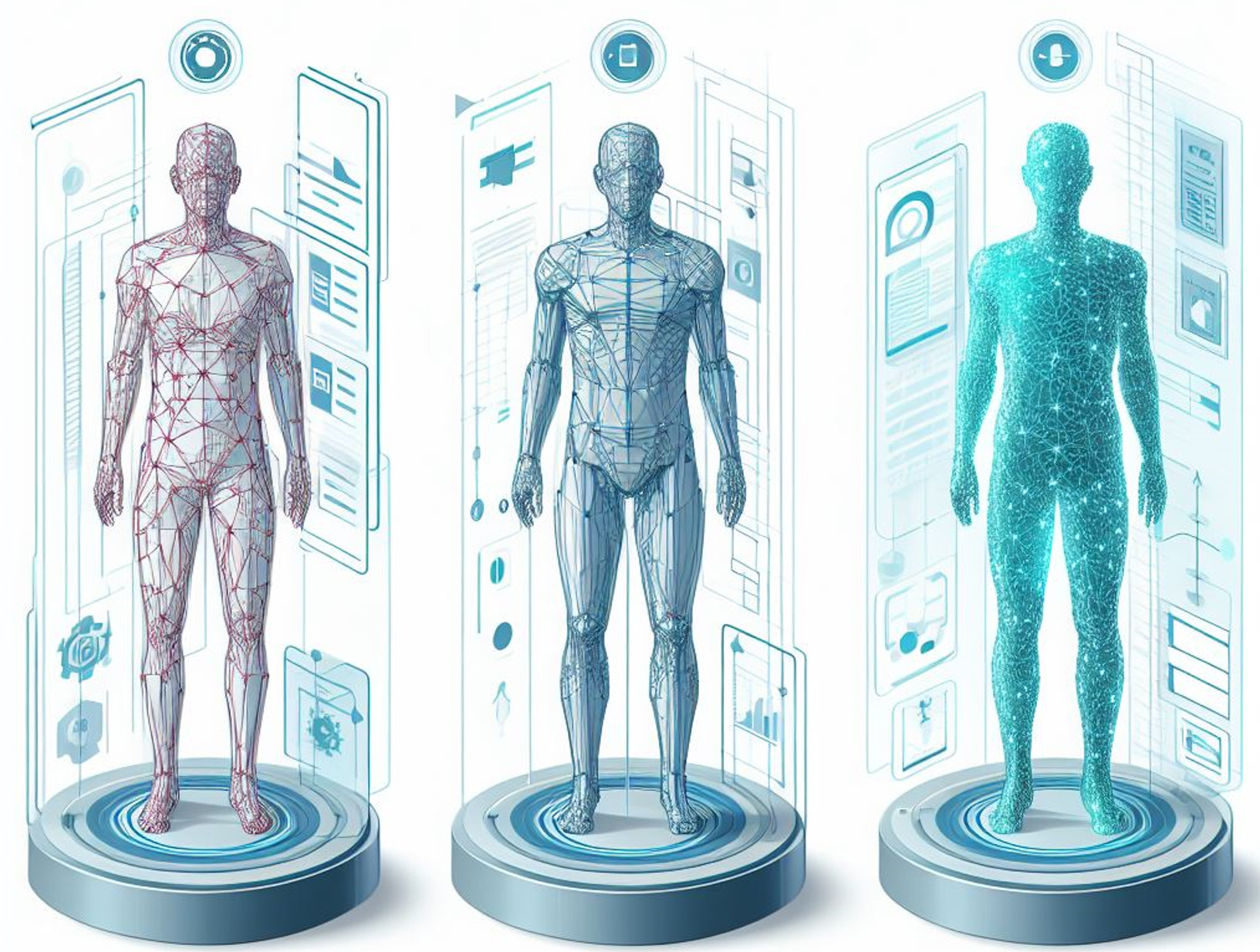

Digital twin integration encompasses three primary levels, namely Digital Model, Digital Shadown and Digital Twin, each offering a different degree of interaction and data exchange between the virtual and the real world.

Digital Model

A digital model is a simplified representation of a physical object or system. It is typically used for design, analysis, or simulation. Digital models can be static or dynamic, and they can be created using a variety of techniques, such as computer-aided design (CAD), finite element analysis (FEA), or computational fluid dynamics (CFD).

Digital models are typically not integrated with their physical counterparts. This means that they do not reflect the real-time state of the physical object or system. As a result, digital models are not as useful for predictive maintenance or anomaly detection.

Digital Shadow

A digital shadow is a real-time representation of a physical object or system. It is created by collecting data from sensors and other sources, and it is updated as the physical object or system changes. Digital shadows are typically used for monitoring, tracking, and optimizing operations.

Digital shadows are integrated with their physical counterparts to some extent. This means that they reflect the real-time state of the physical object or system. However, digital shadows do not have the ability to learn or adapt to changes in the physical object or system.

Digital Twin

A digital twin is a virtual representation of a physical object or system that is updated with real-time data and can be used to predict and optimize the behavior of the physical object or system. Digital twins are integrated with their physical counterparts to a high degree. This means that they reflect the real-time state of the physical object or system, and they can learn and adapt to changes in the physical object or system.

Conclusion

The level of integration in a digital twin plays a pivotal role in determining the value it offers. More sophisticated and deeply integrated digital twins enable a comprehensive range of monitoring, simulation, and optimization capabilities. Whether it's product design, manufacturing, or asset maintenance, digital twin integration is the key to realizing the full potential of this transformative technology, ultimately driving efficiency, cost savings, and enhanced safety across industries.